Our Story

M-Print Manufacturing was founded to bring advanced 3D printed parts to everyone

Mitchell Jackson founded M-print Manufacturing in 2021 and developed his knowledge of additive manufacturing into a business. Mitchell graduated from Texas A&M University in 2017 with a mechanical engineering degree. During his time at Texas A&M University, he learned about different manufacturing methods during his course work and his part time job as a design engineer in a fabrication lab.

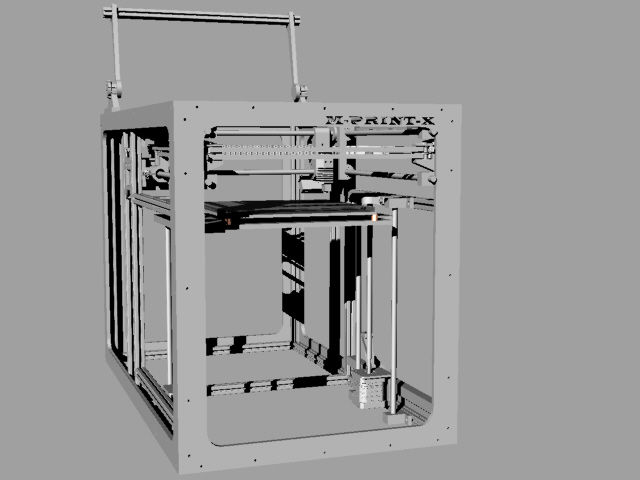

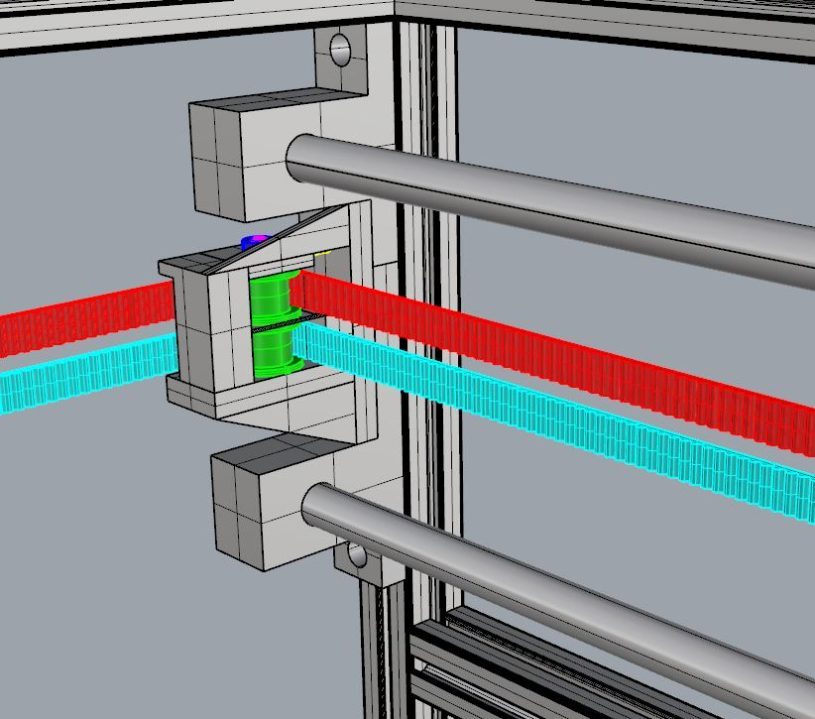

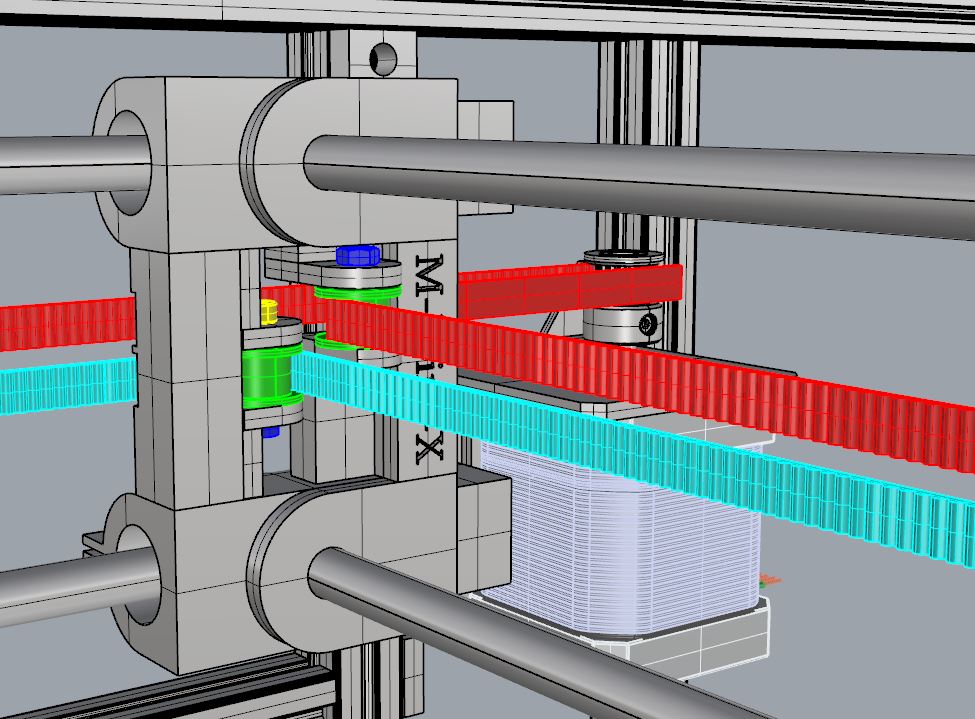

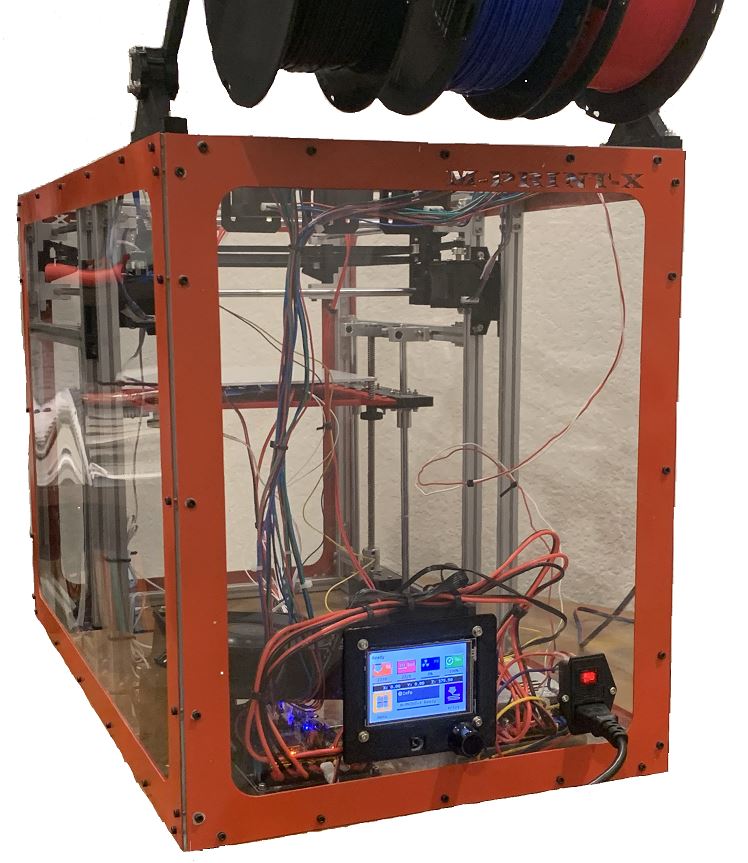

The first printer he built was from a DIY kit for the Prusa I3 which he ordered off the internet. It was during the building of this kit, that he taught himself the basic principles of how to build a 3D printer and still has this running today. The next printer he built was for his senior level capstone project for the Aerospace engineering department at Texas A&M. This printer was expanded beyond the standard abilities by adding several different systems to this printer. One was the ability to print multiple materials with bowden extruders. The second was the develop of a pick and place (PNP) system which is used to seat small electronics into a print like LEDs, or resistors. The last system was a marking tool to display the flex in a soft print. After graduation there was still the goal to continue building printers and develop his skills and lead to the design and creation of M-Print-X. This printer expanded the use of filaments to 3 which can be used in a single print and uses a 32 bit chip for faster communication and quality in print.

After finishing M-Print-X, our company was developed and is located in Ft. Worth, Texas. We continue to produce custom printers, and are continuously upgrading our printing lab to produce better printed parts for everyone.

MPrint-X

Print Lab Video Blog

Find us on You tube to see our latest adventures in 3D printing and now Laser cutting.

In our latest series involving Dual Extruders and the mistakes that are happening as we attempt to print a traffic cone. The traffic cone started off as a simple print that used three colors in one print, however drama has been plaguing us on our experimental printer (Mprint-E4).

Stay tune for all the episodes in this video series!

In the epic conclusion to our video series of dual extruders mistakes, we print the traffic cone . The traffic cone uses three different filament colors in a single print and we show you how to achieve this using a single nozzle and multiple nozzles.

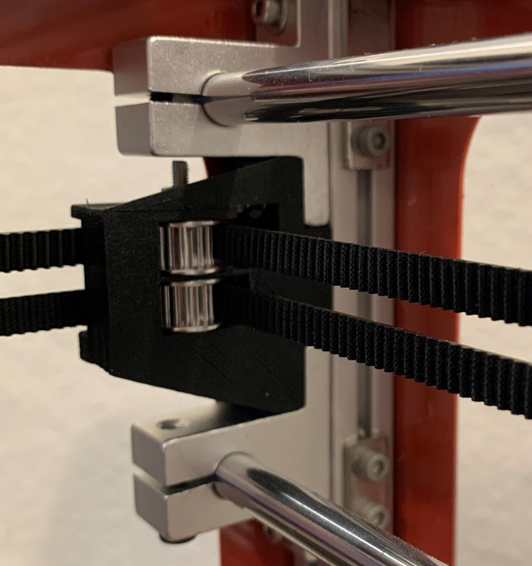

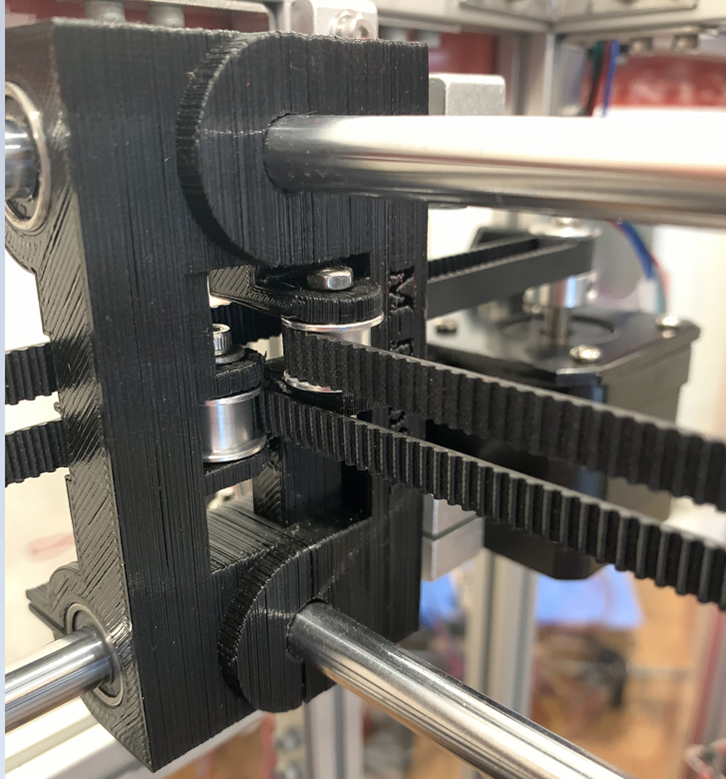

Episode 3: in the adventures of M-Print Manufacturing’s print lab, we find ourselves facing the dreaded maintenance of one printer in particular. M-Print-X needs a new belt or so I thought. Before long I was elbow deep inside a printer asking myself where did it all go wrong